Flexible Wiring and Extension Cords

Control the Hazards of Flexible Wiring and Extension Cords

Electrical cords supplement fixed wiring by providing the flexibility required for maintenance, portability, isolation from vibration, and emergency and temporary power needs. Flexible wiring can be used for extension cords or power supply cords. Power supply cords can be removable or permanently attached to the appliance.

DO NOT use flexible wiring in situations where frequent inspection would be difficult, where damage would be likely, or where long-term electrical supply is needed. Flexible cords cannot be used as a substitute for the fixed wiring of a structure. Flexible cords must not be . . .

- run through holes in walls, ceilings, or floors;

- run through doorways, windows, or similar openings (unless physically protected);

- attached to building surfaces (except with a tension take-up device within 6 feet of the supply end);

- hidden in walls, ceilings, or floors; or hidden in conduit or other raceways.

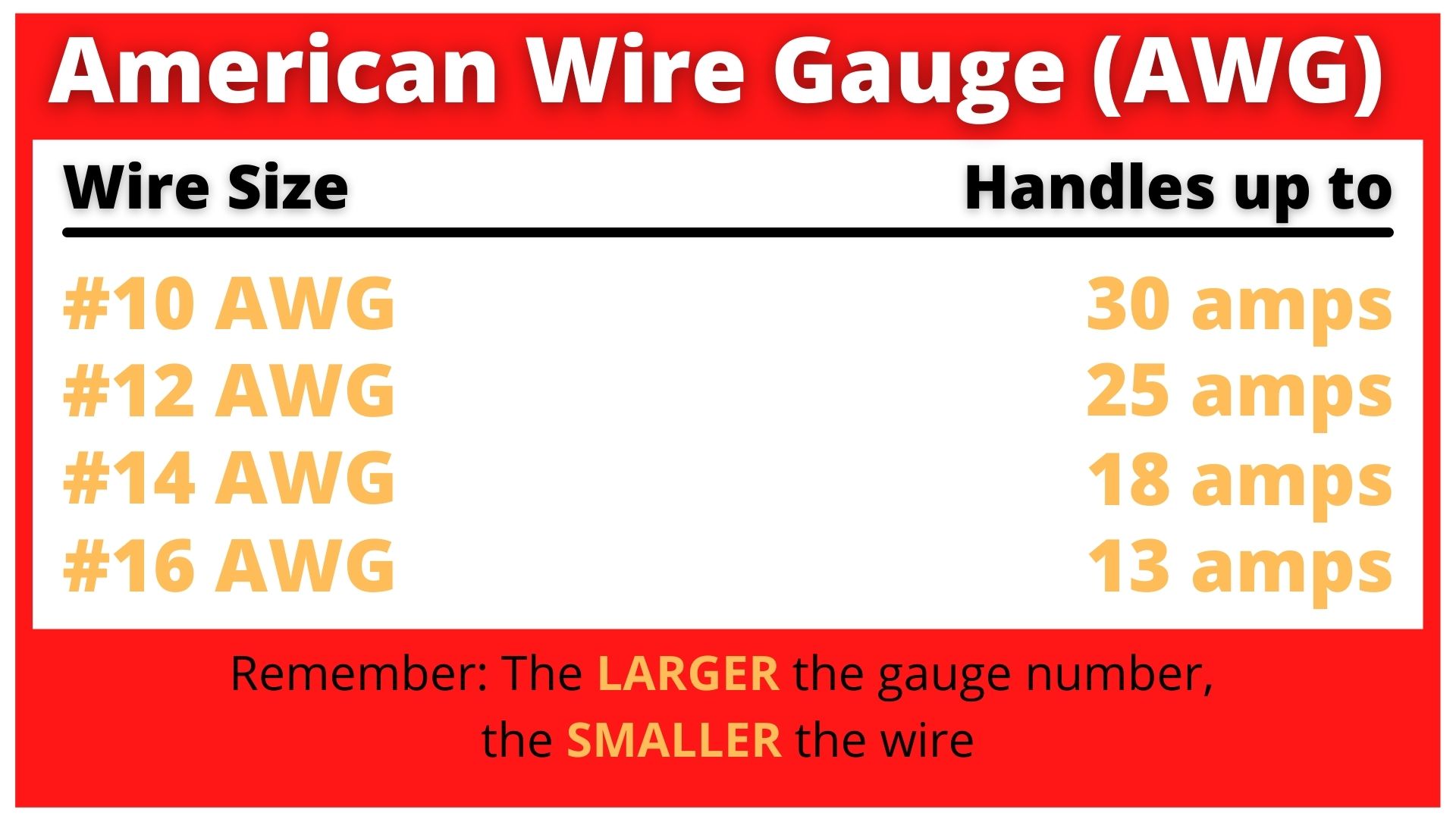

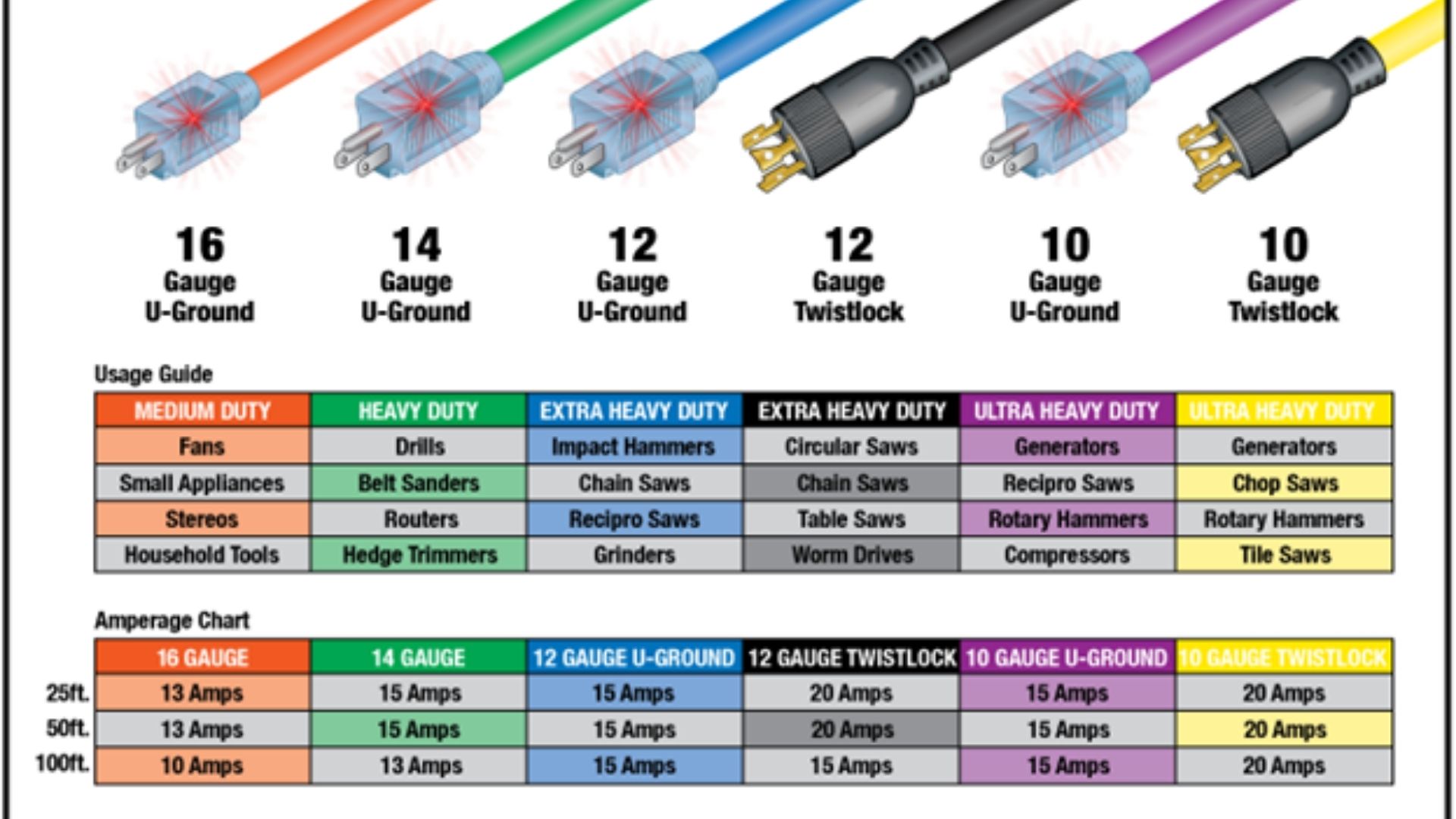

Use the right extension cord. The gauge of wire in an extension cord must be compatible with the amount of current the cord will be expected to carry. The amount of current depends on the equipment plugged into the extension cord. Current ratings (how much current a device needs to operate) are often printed on the nameplate. If a power rating is given, it is necessary to divide the power rating in watts by the voltage to find the current rating. For example, a 1,000-watt heater plugged into a 120-volt circuit will need almost 10 amps of current. Let’s look at another example: A 1-horsepower electric motor uses electrical energy at the rate of almost 750 watts, so it will need a minimum of about 7 amps of current on a 120-volt circuit. But, electric motors need additional current as they startup or if they stall, requiring up to 200% of the nameplate current rating. Therefore, the motor would need 14 amps.

The length of the extension cord also needs to be considered when selecting the wire gauge. Voltage drops over the length of a cord. If a cord is too long, the voltage drop can be enough to damage equipment. Many electric motors only operate safely in a narrow range of voltages and will not work properly at voltages different than the voltage listed on the nameplate. Even though light bulbs operate (somewhat dimmer) at lowered voltages, do not assume electric motors will work correctly at less-than-required voltages. Also, when electric motors start or operate under load, they require more current. The larger the gauge of the wire, the longer a cord can be without causing a voltage drop that could damage tools and equipment. The grounding path for extension cords must be kept intact to keep you safe. A typical extension cord grounding system has four components:

Extension Cord Designations

- S – Notes a general use extension cord that is flexible.

- W – Notes that the extension cord is rated for outdoor use.

- J – Designates that the extension cord has standard 300 voltage insulation in the coating. The lack of a J indicates that the cord has thicker, 600-volt insulation, for heavy use.

- P – Is most often found in air conditioner power cords and household extension cords, that need to be wired in parallel.

- T – Is displayed on an extension cord with a vinyl thermoplastic jacket.

- E – Is displayed on an extension cord with a thermoplastic elastomer rubber jacket. This is sometimes written as TPE.

- O – Notes that the extension cord is oil-resistant(Two OO means that the inner and outer jacket are oil proof)